Services

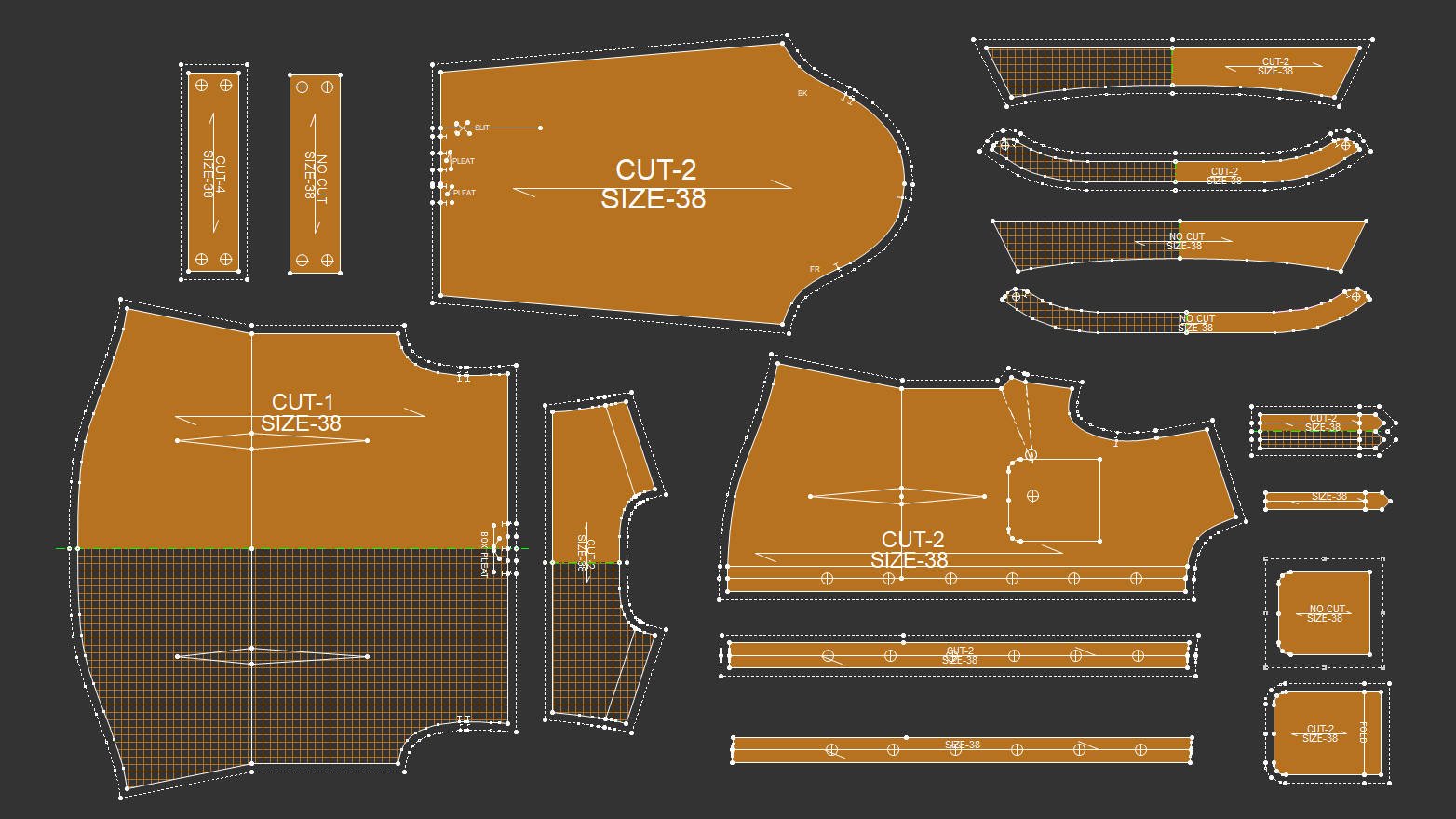

Smart Pattern Design System

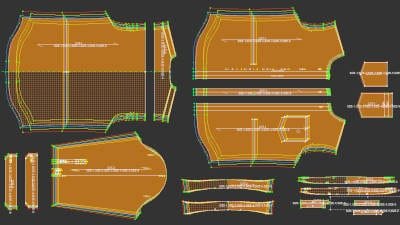

Pattern Design System (PDS) applies the standard Windows icons, exposing users to the maxium operation interface and convenient tool choice. The removable hidden toolbar and dialog box make you easy to create personal work interface. The combination of icon tools and hotkeys maximize the working efficiency. Flexible and various pattern design function make it convenient to design in PDS and digitize the pattern into software by a digitizer. Special file backup: the automatic backup function could help you to retrive the original file even sudden power off and computer crush happen.

One of the most efficient modules. The grading module only takes about 10 minutes to complete the grading task which needs 4 to 5 hours by manual operation, improving efficiency several-dozon times. Pgm Grading Module possesses various grading modes, grading by point, grading by angle, and so on. It could not only grade for every grading point, but also copu the grading value to other point. The system can automatically identify the grading direction accouding to the location of the grading point.

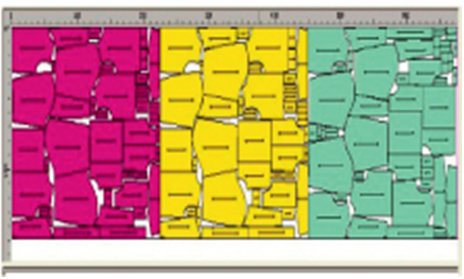

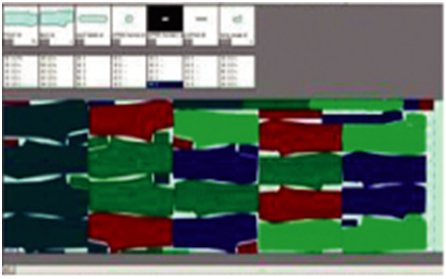

Smart Super Marker Making System

Accumulating lots of experience from tradional marker making, MNC enables to easily complete any coplicated layouts with advanced computer technology, Pgm MNC is more scientific, more accurate, more flexible and more fabric-saving. MNC allows to set one-way, zigzag and tubular working modes, and could rapidly generate nesting results according to the mode set.

Cloth & Cost Redeemable

Suppose your annual fabric cost is $10,000,000, Pgm smart super Marker will save $150,000 for your fabric cost every year. Suppose your annual fabric cost is $20,000,000, super nesting will save $300,000 for your fabric cost every year. Labor & time saving Nesting Queue generates compete and multiple nests by automatically using unattended overnight processing, which avoids working overtime. Energy saving super nesting provides EXCEL report to show fabric consumption rate, length and so on conveniently and accurately.

Pgm Smart 3D Fittings & Photo Realistic

Save time and money creativity with influential and flexible 3D imagining of your designs using 3D sampling suite. You can turn your flat patterns into 3D models and instantly see the results of any changes on the pattern. You can get perception as to how alteration in style, fitting, material type and design will effect of the final stitched product. The photo realistic module will get you real fabric constructing and color.

Smart Car Seat Flattening

Pgm’s automotive seating design-to-manufacturing process is divided into three phases: PRE-PROCESSING – creating a reliable digital representation of fabrics, leathers, and technical materials. The process is initiated by conceptual design of the seat, determined by customer-specific demands, using Pgm 3D design software. It’s then exported to PDS 2D/3D, an integrated 2D & 3D workspace that simplifies positioning and modifying the pieces back and forth between the two dimensions. This enables a fast and accurate flattening process that allows the faces of a 3D model to be extracted.

Pgm Smart Grading Module

One of the most effective units. The grading unit only takes around 10 minutes to complete the grading task which needs 4 to 5 hours by manual operation, improving efficiency several-dozen times. Pgm Grading Unit possesses numerous grading modes, grading by point, grading by angle, and so on. It could not only grade for every grading point, but also replica the grading value to other point. The system can automatically identify the grading direction according to the location of the grading point.